2W-2S BTA is especially designed for vibration absorber during deep hole drilling

Unique coolant system ensures the effect of surface smoothness after machining. The system exhausts chips by using high-pressure coolant through holes in the tool head, out the drill tube, and through the machining spindle. It provides an ideal solution for long tube’s deep hole drilling

2W-2S BTA adopts vertical type configuration, with a short loading/unloading distance to facilitate operations

Excellent chip disposal performance and easy maintenance

| Specification | 2W-2S NC BTA SPM |

| Part length | 260~400 mm |

| Machining diameter | Ø26~42 mm |

| Travel Z-1 & Z-2 | 400 mm |

| Rapid traverse | 30 m/min |

| Spindle speed | 2400 rpm |

| Spindle motor | 15/11 kW |

| Spindle bearing inner dia. | Ø85 |

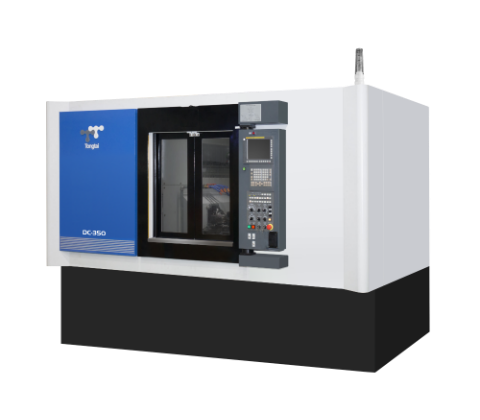

DC-350 is especially designed for differential case machining. For ensuring excellent machining accuracy, the workpiece only needs one-time clamping and all machining tasks are able to be finished in one single machine

BBT-40 belt-driven spindle provides outstanding machining performance. Furthermore, through the collaboration of two spindles and two tool magazines, it dramatically saves the machining time.

The rear type chip disposal design allows machines to be compactly placed. That benefits on plant utilization

| Specification | DC-350 |

| Table size | 400x400 mm |

| X/Z axis travel | 350/350 mm |

| X/Z axis rapid traverse | 18/14 m/min |

| Spindle speed | 12000 rpm |

| Spindle motor | 15/11/7.5 kW |

| Spindle taper | 7/24 Taper No. 40 |

| Tool capacity | 12 pcs |

© copyright 2020 by Astra Machine Tools Pvt ltd | Designed by 360degreeinfo